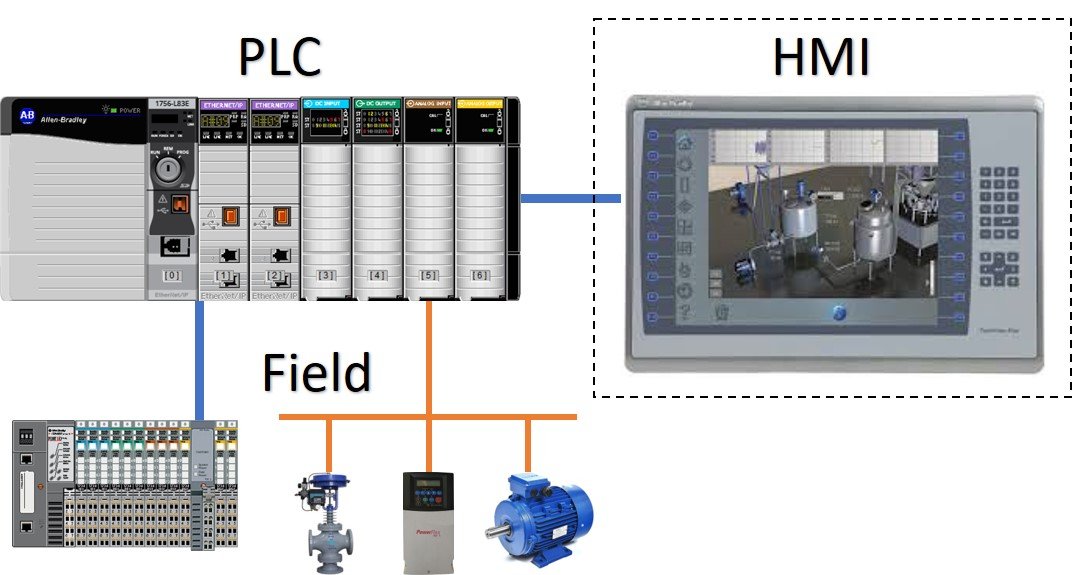

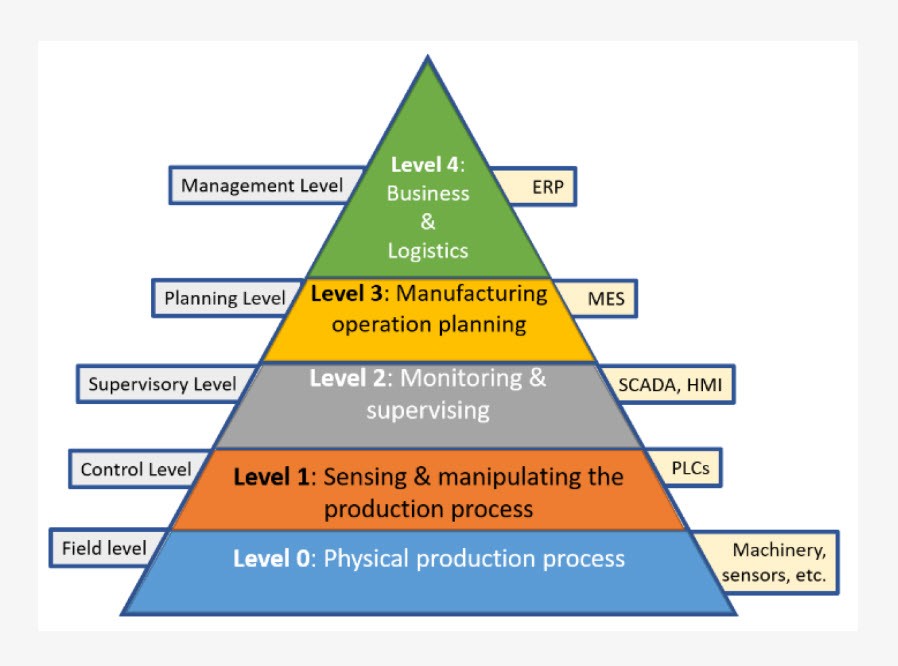

Industry 4.0 follows the goal of promoting digitalization of manufacturing. Our programming methods and standards are designed to act more intelligent and provide interfaces to other technologies like SQL databases, cloud computing and Cyber Physical Systems. We have more than 20 years of experience in PLC programming for various industrial applications for OEM and manufacturing plants. Some of the machines we programmed integrate with legacy devices such as RS232 printers and scanners. We are very proficient in bringing PLC data to SQL servers using advanced communication protocols and bring the shop floor data to your MES or other business applications.

HMI is the most important interface between PLC and machine operators. The HMI program must allow users to closely monitor machine performance , track production and respond to changing maintenance and production demands. It should help to improve efficiency and reduce downtime. Our new HMI programs are designed as per ISA101 standards. Our programs will have menu hierarchies, screen navigation conventions, graphics and color conventions, dynamic elements, alarming conventions, security methods and electronic signature attributes.

Data has emerged as a fundamental resource for the Smart Factory. Data collection from the shop floor machines and integrating it with business application is the key for achieving Industry 4.0. We have an extensive experience in PLC integration with MES applications using SQL database. We can help with database design for your machines and manufacturing plants, data collection programming and database administration. Once you have data in the industry standard database then you can feed it to other business applications for advance reporting and data analysis.

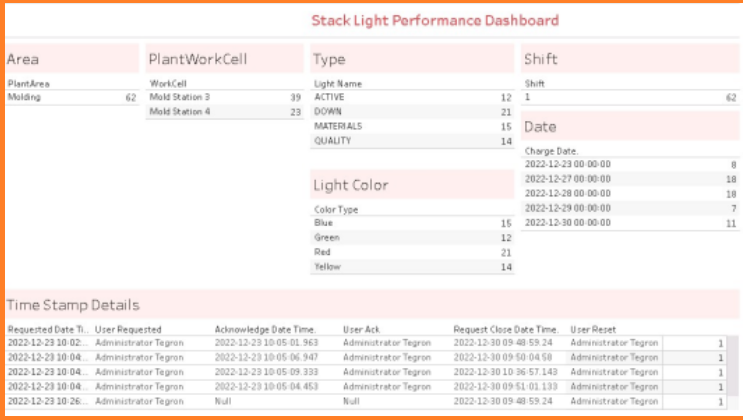

Tableau dashboards are very popular data visualization tools used to analyze and explore data in a meaningful way. Manufacturing analytics can improve process efficiency, centralize production monitoring, better serve your customers, and turn real-time data into just-in-time insights. We have built several tableau dashboards for MES and financial applications. Our MES dashboard provides a complete overview as well as detailed analysis of the shop floor. We also have a dashboard built for inventory control, material consumption and financial statement analysis for each month.

Overall equipment effectiveness (OEE) is a measure of how well a manufacturing operation is utilized (facilities, time and material). It identifies the percentage of manufacturing time that is truly productive. An OEE Dashboard is a production reporting feature that displays real-time OEE scores for easily accessible consumption across the shop floor. Our OEE dashboard is built using tableau and has real time data collection from MES and PLC for accurate reporting.

Microsoft Power BI is an interactive data visualization software product developed by Microsoft. Power BI for manufacturing acts as a guiding light, providing comprehensive visibility into operations, supply chains, sales, and other critical aspects. Our Power BI dashboard for MES helps our current customers to perform real-time analysis of their manufacturing process. It helps them to improve their productivity and reduce downtime.

Industry 4.0 factories are complex, and data driven. Data is used to control and optimize manufacturing processes and improve overall productivity of manufacturing process. In today’s world data needs to be collected from many sources like PLC, Drives, Sensor, business applications. Our proven solution. Our proven solutions allow our customers to collect data from PLC using advanced communication protocols. We can Read and write data to Allen Bradley, Siemens, and Modbus devices, Universal Drivers, OPC, OPC UA, databases, Excel.

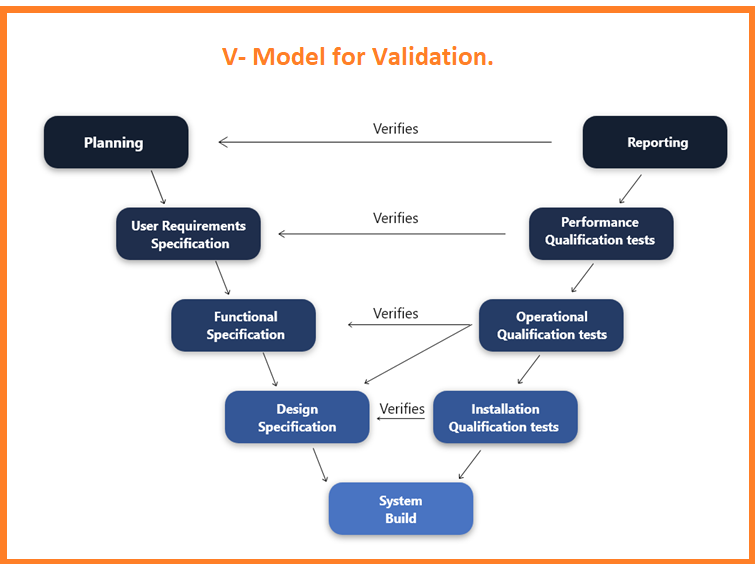

Equipment validation is a documented process demonstrating whether a piece of equipment, system, or process consistently produces results within predefined specifications. This process ensures manufacturing equipment performs reliably and consistently, reducing risks and safeguarding patients through regulatory compliance and quality products.

We have helped our customers to write validation documents and execute validation protocols. We can prepare URS,FRS, DDS, IQ, OQ, PQ document for your machines and help you to qualify your machines are per 21 CFR part 11. We also do Computerized system validation as per FDA 21 CFR Part 11.

Commissioning of VFD is the process of checking, inspecting, testing, and configuring the equipment at the project site. We provide all necessary technical support and manpower to our customers for their commissioning needs. We have extensive experience in integrating VFD to PLC system and data collection for troubleshooting and performance review of the overall equipment.

Get an access to our expertise and innovations before you invest.

contact us